Material Handling Carts Designed for Industrial Equipment Manufacturing

Last Modified: 11/02/2022

FlexQube manufacturing carts are built for transporting and presenting large and heavy materials, and we have worked alongside many Heavy Duty Industrial Equipment manufacturers.

FlexQube solutions have been able to help these customers create manufacturing carts that are durable enough to withstand the heavyweight of the materials, not only for static force but also dynamic force. We think moving the equipment easily is a part of increasing efficiency. FlexQube carts are easy to move, robust, and last over time.

Even though our material handling carts are heavy-duty, it is also possible to rearrange the cart after your requirements. If your materials change, you can also change your FlexQube material handling equipment. You don’t have to through used material handling carts away, simply just update and improve your warehouse carts. It will save you both money and time.

Below we have outlined a number of material handling carts that have been created and are currently used by large industrial equipment manufacturers, in the USA, and throughout Europe.

Shelf Cart 1260 x 048 MM – Q-100-0957

This 1260 x 840 MM shelf cart is designed to transport a kit of materials to the assembly line. The parts can be anything from boxes too heavy hydraulic motors. It is equipped with a handlebar for manual pushing by an operator. However, this manufacturing cart can also have a tow bar added on to be towed using a tugger train system. This particular cart is lifted by a bridge-type mother frame but can also be towed using another tugger train system or with a tow bar. Placed on the top shelf is also a thin layer of rubber to provide further protection of the parts.

Shelf Cart with Fence 1196 x 706 MM – Q-100-0123

This shelf cart is equipped with four shelves and is ideally designed to transporting heavy totes and bins. This cart is equipped with two handlebars for manual pushing by an operator. However, it can also be equipped with a tow bar if needed. This material handling cart comes equipped with a fence around the outside to ensure the materials are secured onto the shelves. This cart is used by a large industrial equipment manufacturer in Sweden. They have a kitting process with manual movement between the warehouse and assembly line. The cart is lifted by an order picker to be filled with a variety of bins, parts, and heavy metal parts. Then sequenced to the line where they assembly huge equipment for the forestry industry.

Cart For Hanging – Q-100-0384

This heavy-duty material handling cart is ideal for efficiently and easily transporting materials that need to be hung, such as wires, cords, ropes, and small exhaust systems. This cart is equipped with a foot release tow bar for improved ergonomics when releasing from a tow truck. However, if needed, this cart can have the tow bar removed and handles added to the sides for manual pushing by an operator. This particular solution was sold to Cummins Motors in Mexico.

1260 x 840 Shelf Cart With Additional Extendable Shelf Cart – Q-100-0738

This warehouse cart is similar to the above Q-100-0957; however, it is equipped with a 100% extendable shelf on the bottom. This provides more ergonomics and efficiency in removing heavy parts from the cart, as the extendable shelf improves access to the materials. This manufacturing cart is equipped with a handlebar for manual pushing by an operator, to transport it from the tugger train to its spot on the line. However, it can be equipped with a tow bar for transporting via a logistics tugger train.

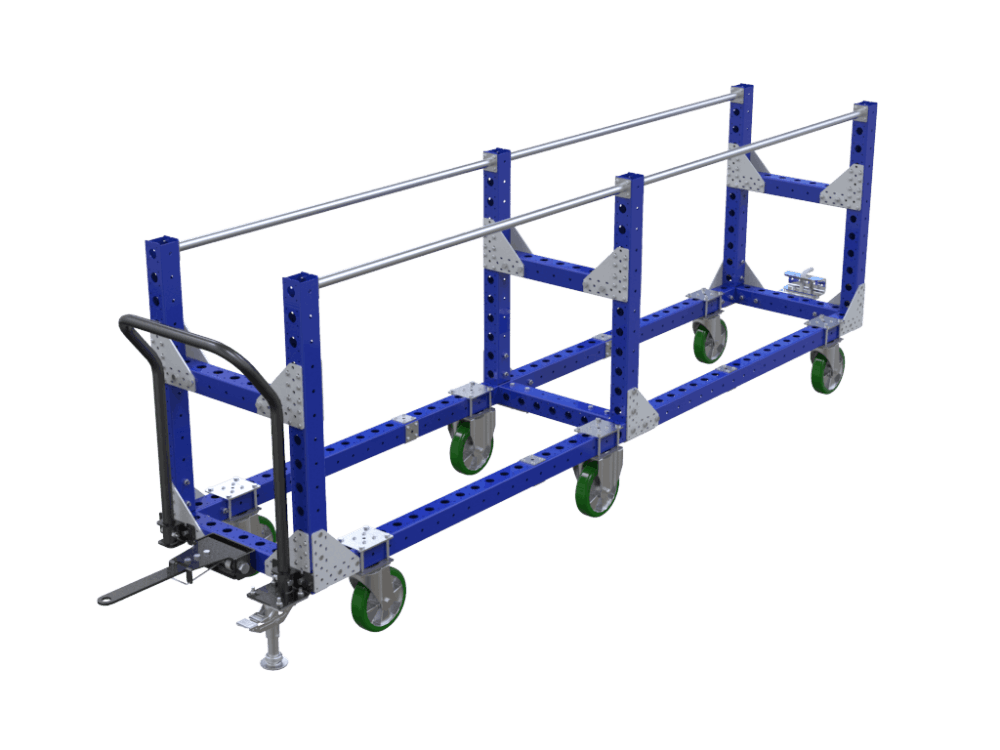

3080 x 630 MM Tube Cart – Q-100-0955

This long and heavy-duty tube cart is designed for transporting very large and heavy materials. This manufacturing cart comes equipped with a handlebar for manual pushing and a tow bar to be towed by a tugger train. It also comes equipped with a floor lock brake to secure the cart and materials in place.

Kit Cart for Cylinder Blocks 1260 x 1260 MM – Q-100-0203

This kit-cart/ pallet cart was specifically designed for transporting cylinder blocks. This manufacturing cart was designed with a higher base to improve ergonomics for the operators. This cart is equipped with both a handlebar and a foot release tow bar for transportation via the tugger train system.

To reach your warehouse full efficiency potential, you have to take your warehouse material handling equipment handling into consideration. Questions such as routes, stations, materials, distance, and ergonomic play an important role when making decisions about what type of industrial material handling carts you should go for. Going forward, automated material handling solutions is also something to consider.

Here are some useful tips when choosing your warehouse material handling equipment:

- Determine the most appropriate distance that should be covered.

- Facilitate material damage reduction in order to improve their quality.

- Reduce total manufacturing time through well-designed material movement.

- Enhance the flow control of materials.

If you want to learn more about warehouse material handling, and what to take into consideration when choosing material handling carts, please read our blog post ” A Guide To The Basics of Successful Material Handling”.