Some Questions with our Design Manager for Mexico

Cinthia Gutierrez is FlexQube’s design manager for the Mexico and Spanish markets. She works very closely with Hector Flores, our sales manager in Mexico and together they have implemented several successful material handling projects at customers in Mexico. Mexico has become a very important market to FlexQube and we believe that the great solutions that Cinthia has designed provide a lot of value to the operators and facilities.

On top of this, along with our European Project Manager Amir Chihani, we are looking forward to developing the FlexQube concept in Spain and show the value we have been able to provide in other locations.

We are thrilled to have her on board the team and we were able to ask her some short questions about the design process and her work in general. We hope this can help you understand the design process and learn a little more about the FlexQube concept.

1. How long have you worked with FlexQube as a designer?

I have been working with FlexQube for 11 months, on the 23rd of October this year I have spent one year with FlexQube.

2. In that time, what have been some of your favorite designs you have created with FlexQube?

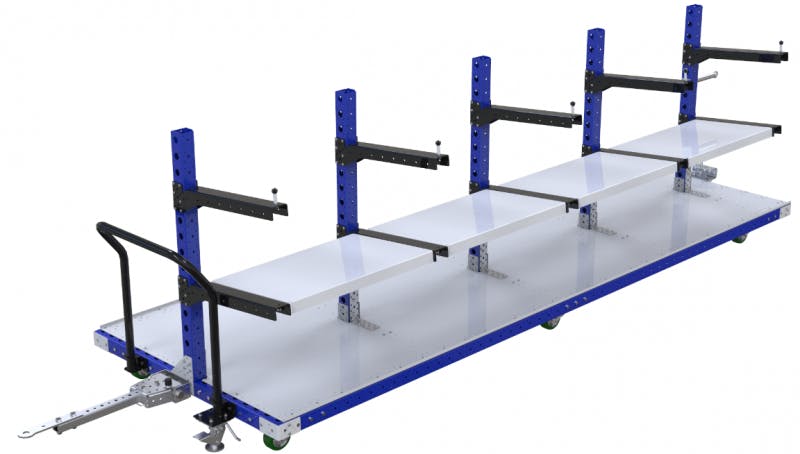

One of my favorite designs was the Kit Cart 1330 x 3920 mm, number Q-100-1486, because we were able to create a single cart that could manage different types of materials. All these materials were destined for the production area and had to be assembled in a specific order. It’s interesting for me to see how different industries are using different materials and I really enjoy seeing our carts help them improve their processes and material flow.

3. What has been the most common types of carts in the Mexican market?

The most common type of carts that I have designed or modified for the Mexican market is pallet carts/ flatbed carts, shelf carts and carts with rollers. I think that the clients that have previously worked with us mostly transport their materials using pallets, containers and different sizes and weights. This makes it easy for us to adapt our carts to different materials and the different weights, so the carts match the materials. In many of the facilities we have visited they are using forklifts, but we are beginning to see a trend of tugger train systems being implemented. This allows for a train of carts and frames to transport the materials, this greatly improves the efficiency of the transportation instead of using forklifts for this purpose.

4. What is a very convenient function in a cart that is often overlooked?

I think that our tow bar with foot release is a very convenient function to improve the ergonomics for the operators, especially when the carts are used in a tugger train. Many clients choose the standard function for connection with the hole and pin, but I consider the foot release tow bar one of the most beneficial functions on our carts.

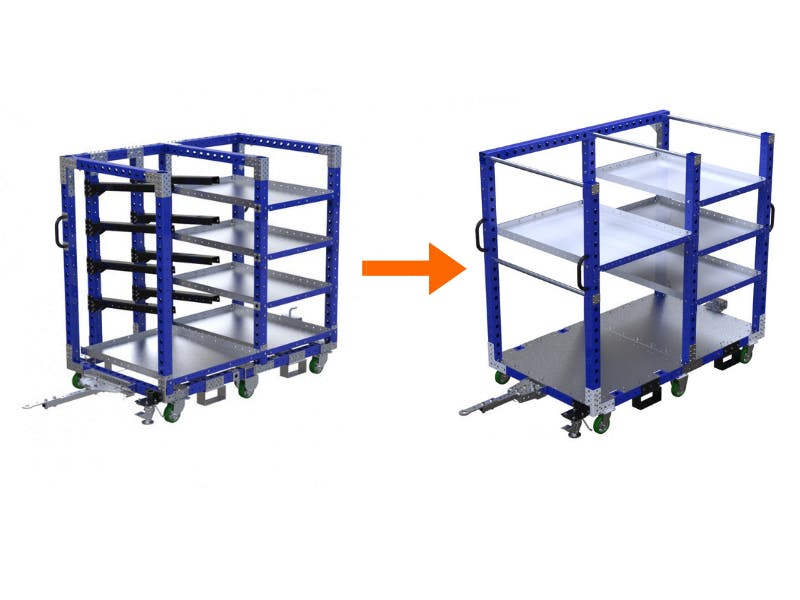

Also, I believe the fixed shelves for the shelf carts are the most popular, but the extendable shelves are a great option to use in the lower levels of shelf carts. This gives the operator greater access to the materials they need to either place or remove from the shelf.

5. How can a person who has booked a design meeting be prepared for the day of the meeting?

It is important to have the dimensions and weight of the materials that the cart will be transporting or presenting. Also, the way they need to be placed and removed from the cart can be very useful. How you are looking at transporting the carts is very important, will they be used in a tugger train system, manually pushed, or via forklift? Bonus details would be the size of the aisles, will they run indoors or outdoors, do you want brakes on the cart? This information helps us in getting the design process started or if we have a previous solution designed that we could recommend.

If you want to book a DesignOnDemand meeting with Cinthia to begin the design process, you can email her at cinthia.gutierrez@flexqube.com

If you are interested in any of the above solutions or would like to contact Hector Flores, our Country Manager of Mexico, you can contact him at +52 (449) 138 9198 or hector.flores@flexqube.com

You may also like:

How to improve productivity in your warehouse in 3 steps with push carts