Burckhardt Orders Over 100 Material Handling Carts from FlexQube

FlexQube received an order from Burckhardt in Switzerland in April of 2020 to deliver over 100 smaller material handling carts. The beginning of this process was all the way back in October 2019 when Burckhardt first reached out to FlexQube GmbH.

After the first visit to Burckhardt’s manufacturing facility, it was clear that a normal welded trolley would not fit their needs. The metal materials that Burckhardt was transporting within their facility were very heavy and the space between their machinery was quite tight. As with many facilities, the amount of space to move materials is getting tighter and tighter. It was obvious that a solution designed specifically for their needs was the right option.

Following this first visit, online meetings were set up between the customer, our sales engineer, Jan Brettmann, and FlexQube’s design team. During this process, the needs of the customer were outlined and a few designs were offered. From which one was selected and an initial prototype was built.

So the operators and engineers on-site at Burckhardt could become more familiar with the FlexQube concept, this first prototype was built onsite in their facility, with the help of FlexQube’s sales engineers. This was of great benefit to the customer because they were able to see first-hand, how easy it was to build a FlexQube cart and if needed in the future alter it once again. Following the testing of the prototype, a few minor details were needed to be changed to the design before the order of 100 more was finalized.

These material handling carts fit perfectly to Burckhardt’s needs and this will improve their material handling production greatly.

Shelf Tugger Cart – 420 x 630 mm – Q-100-3368

This small shelf tugger cart is ideal for transporting smaller materials within tight and narrow spaces. It has two levels with lips along each of the sides to keep the materials in place. It comes with a small ergonomic handle for easier handling by operators and a tow bar so it can be transported within a tugger train.

Transport Cart – 630 x 980 mm – Q-100-3450

This custom-designed transport cart was created to transport heavy but small, metal materials more efficiently. It comes with flip-down shelves on each side which makes it easier for the operators to access the materials. This transport cart is also equipped with an ergonomic handlebar and a tow bar so it can be transported within a tugger train system.

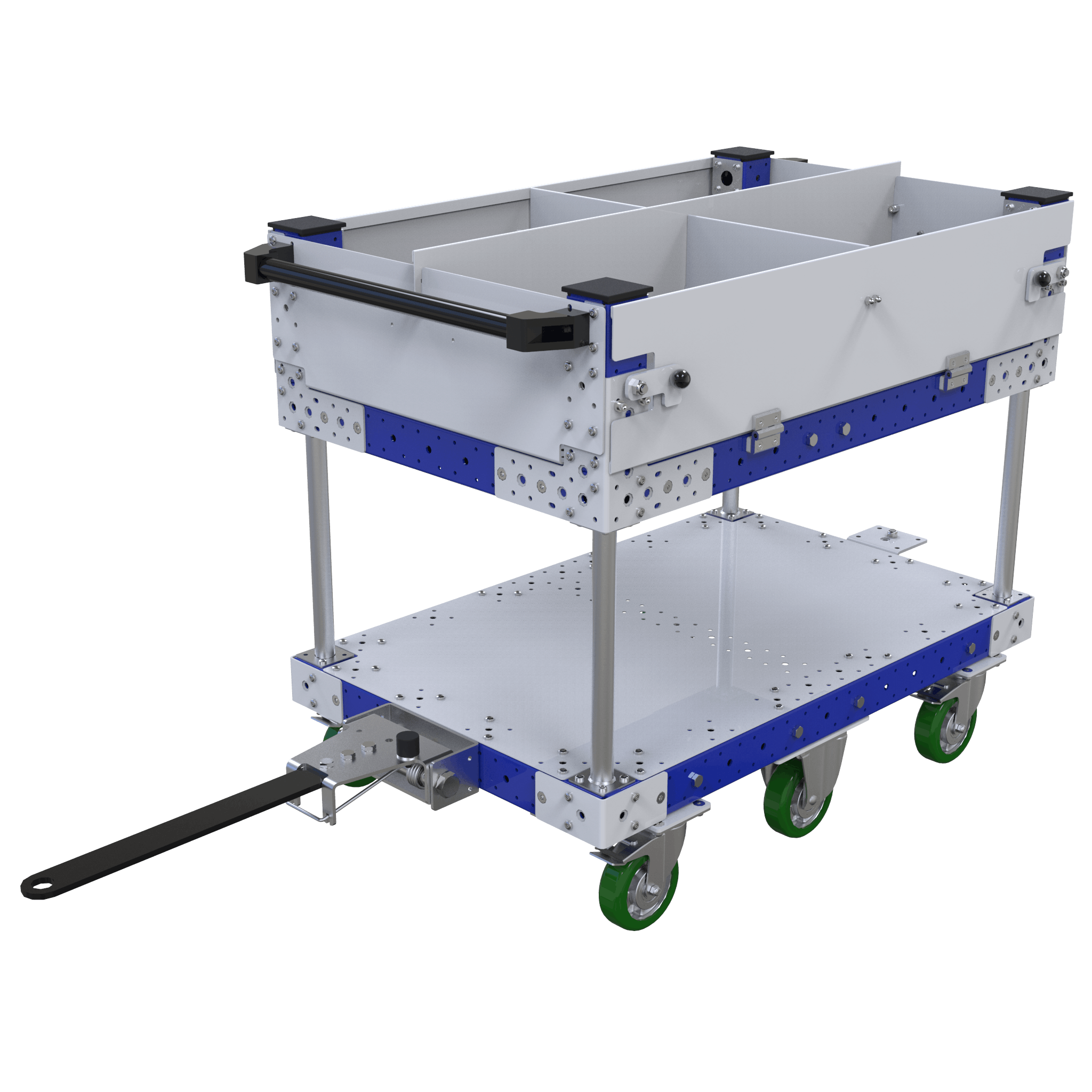

Transport Cart – 840 x 1400 mm – Q-100-3454

This two-level flat shelf tugger cart was custom-designed to transport small but heavy materials. The top shelf has been split into four separate sections with removable dividers to help sort the parts and materials. The long sides on this cart can fold down making it easier for the operators to access the materials. This material handling cart also comes with an ergonomic handlebar and a tow bar for easier manual transportation and transportation in a tugger train.

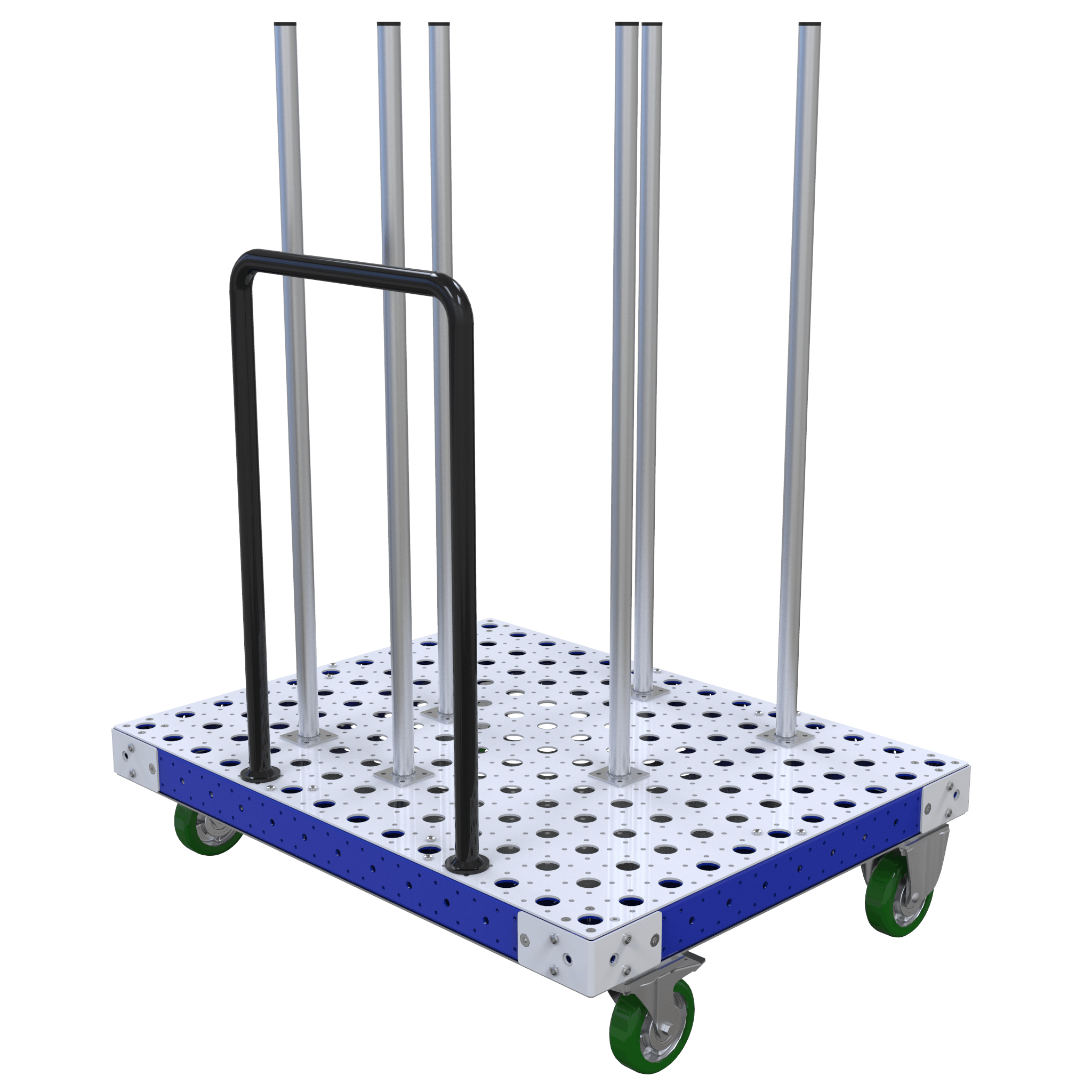

Kit Cart – 980 x 770 mm – Q-100-3589

This kit cart is designed to move panels and different sized circular components more efficiently. The tubes that are placed into the top plate are movable and can be rearranged based on the different materials that need to be transported. This cart also comes with a handlebar to make it easier for the operators to maneuver the cart.