Top 5 Material Handling Carts and Equipment

In today’s fast-paced world, optimizing efficiency within a facility is crucial for businesses to optimize their warehouse workflow. Research conducted by Persistence Market Research has projected significant growth in the material handling carts market, with its value estimated to rise from US$ 680.8 million in 2023 to US$ 1.29 billion in 2033. The rising demand for material handling carts and equipment stems from the increasing necessity to enhance operational efficiency and safety in manufacturing and production facilities, where automation and robotics are being progressively implemented.

What are Material Handling Carts?

Material handling carts are equipment used for safe and efficient transportation of materials. Material handling carts are typically used within the internal transportation line in manufacturing and production facilities. They can be manual and automated and are used in various industries to transport low-weight and heavy-duty materials.

At FlexQube, customers have the freedom to tailor various features of the material handling carts to suit their specific material handling projects. This includes customizing features such as caster adjustments, top structures, handles, and cart size, as well as configuring both manual and automated material handling carts.

Why is material handling carts and equipment important in manufacturing?

Material handling carts and equipment are important for improved efficiency, safety, flexibility, time management, and space utilization. Material handling carts help streamline the processes by transporting different materials simultaneously, giving operators more time for other tasks than separate transportation. It also decreases the need for manual labor and minimizes injuries that often occur when transporting heavy materials.

Also, material handling carts are designed to maximize transportation capacity and flexibility by transporting a high variety of materials in often-times small areas, which operators can adjust thanks to customizable top structures and scalable base structures based on their changing needs.

What are the top 5 material handling carts?

- Tugger Carts: This cart is designed to be towed by a tugger train. It is customizable and can be equipped with shelves, bins, and racks to transport materials or finished goods.

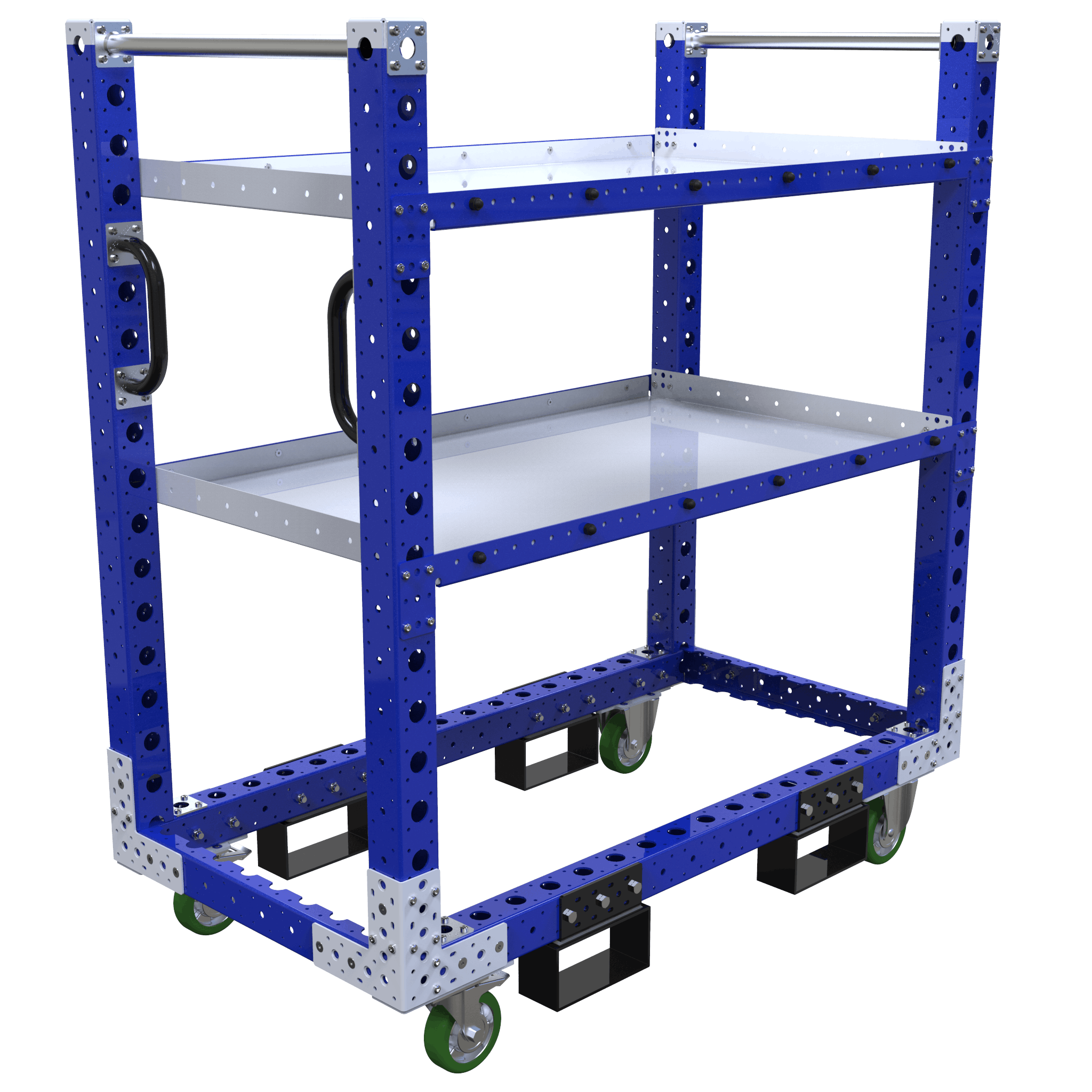

- Shelf Carts: This cart is ideal for storing and transporting smaller items or parts. It is equipped with adjustable shelves and can be easily customized to fit specific needs.

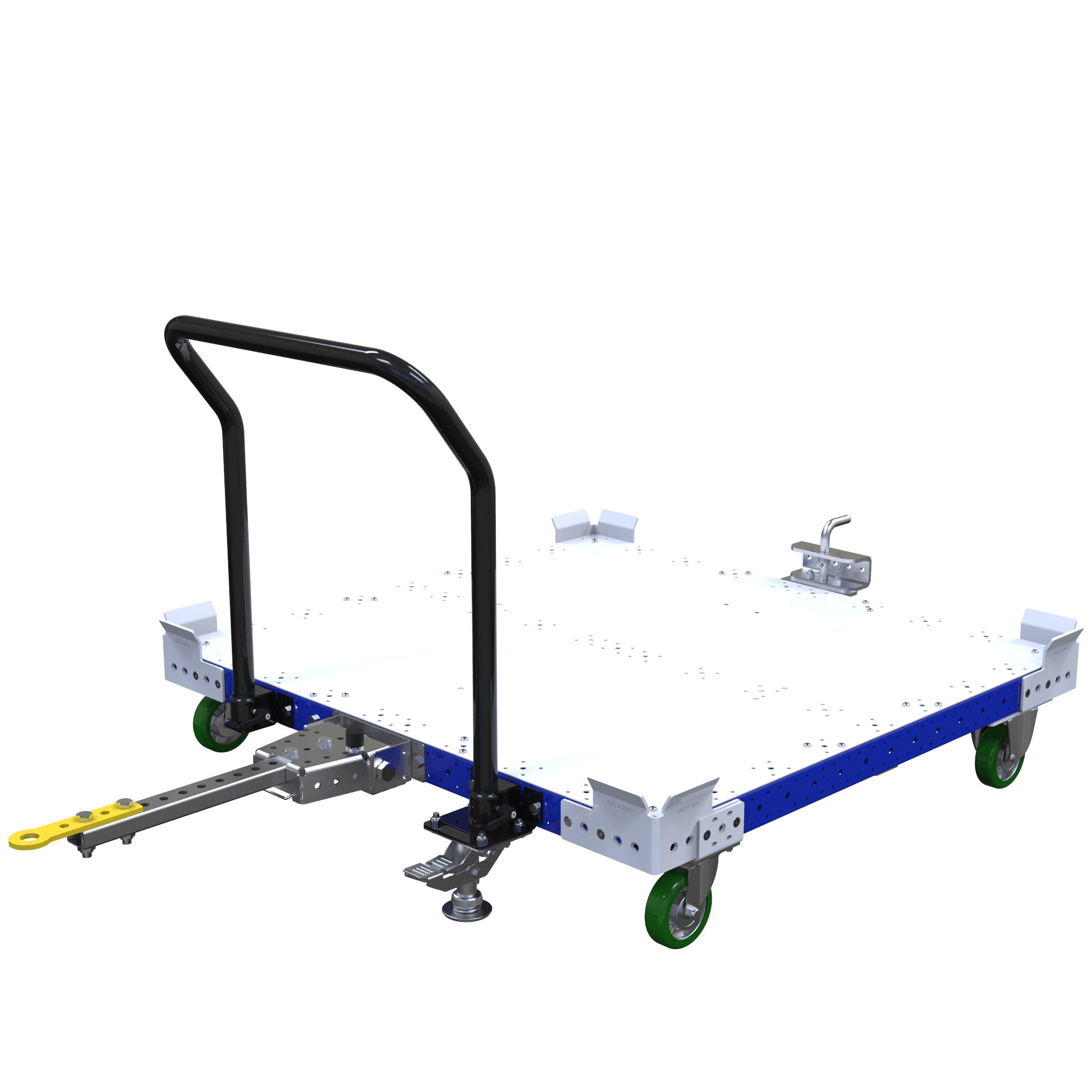

- Pallet Carts: This cart provides a large, flat surface for transporting larger items. It can be equipped with handlebars, tow bars, or side panels to secure the load during transportation.

- Flow Shelf Carts: This cart is specifically designed for the flow of materials in production lines. It allows for easy picking and replenishment of items, enabling efficient material handling.

- Kit Carts: This cart is designed to transport pre-assembled kits or components. It can be customized with dividers, bins, or foam inserts to securely hold the kits and prevent damage during transportation.

Automated material handling carts

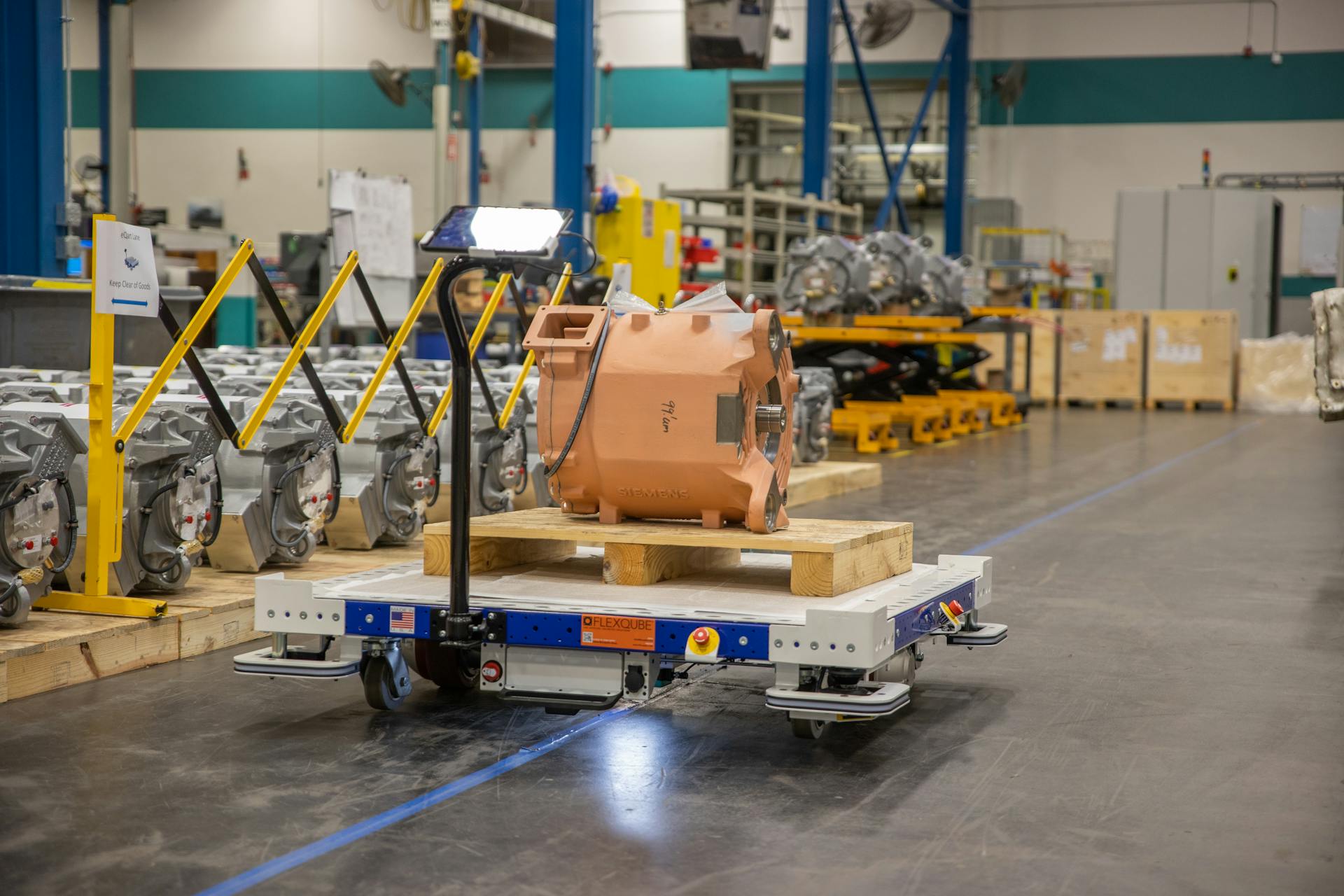

As the market demand for automated material handling carts is increasing, FlexQube has developed a smart, safe, scalable, and successful automation cart for material handling.

The AGV system (Automated Guided Vehicle) is an autonomous and remote-controlled material handling cart. It is designed to offer a flexible, affordable, and user-friendly automation concept. It consists of standardized building blocks but is additionally equipped with smart modules such as a motor, battery, cameras, and sensors that enable it to navigate automatically. The AGV system enables customers to customize any manual FlexQube cart to become self-driving.

The AMR system (Autonomous Mobile Robot) is a non-load-carrying AMR, which enables the robot to move freely and docks into carriers through a standardized coupling. The carriers are customizable, which creates flexibility for operators to transport a wide variety of materials.

Got Questions? Contact Us Today

-

U.S.

![]()