Autonomous Robots: How they bring innovation

Customers now want and pay for same-day deliveries, making the 3-day delivery timeline outdated.

According to statistics, 61% of consumers will choose to buy items from businesses that offer reduced delivery timelines over brand loyalty. Enterprises that intend to keep their customer base and attract prospective customers must implement smart intralogistics to meet today’s expectations. This is where autonomous robots and guided vehicles have crucial roles to play.

Intralogistics refers to the process of optimizing, integrating, and managing the flow of inventory and information within manufacturing facilities, warehouses, and distribution centers. Getting the optimization process right involves implementing a high-performing material handling strategy to manage the material flow. Autonomous guided systems enhance the successful implementation of material handling strategies by automating order picking, transportation, collaboration, and safety within the shop floor.

Robot-Assisted Order Picking

Timely order-picking processes support lean manufacturing initiatives such as just-in-time deliveries of raw materials, tools, and packages on the shop floor. Automated item picking involves the use of inventory management systems to track items and inform robots concerning pick-up and drop-off locations. Within well-organized floors, robots utilize inventory data and path planning technology to find the shortest obstacle-free pathway to its delivery point.

The automated material equipment generally consists of a robotic arm mounted on an autonomous guided vehicle or platform. Advanced robotic arms can identify inventory using machine vision and are equipped with multiple axes of rotation that provide dexterity. The vehicle or carrier systems transport picked items to their destination.

Robot-assisted picking solutions may also serve simpler material handling needs such as extracting items from storage and placing them on pallets or bins. These pallets or bins are manually carried and transported to workstations where they are required. Thus, providing direct assistance through automation to technicians and order pickers on the shopfloor.

Automated Material Transportation

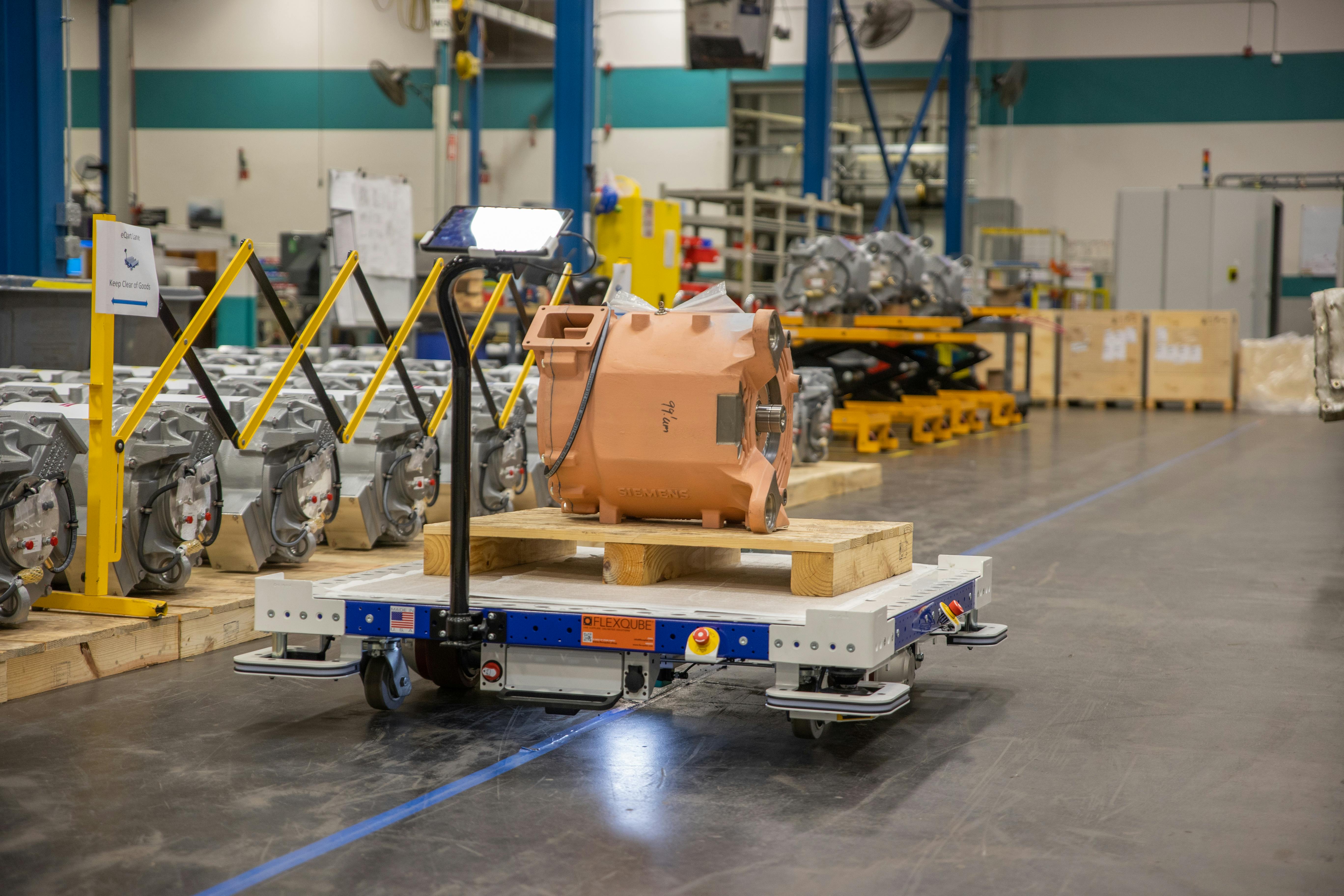

Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) are autonomous systems capable of transporting large or heavy equipment across the shop floor. At the base level, these autonomous systems utilize machine learning and triangulation technology powered by sensors to measure the distance across objects and tracks such as magnetic tracks.

AMR robots that utilize machine learning can support free-roaming navigation where they seek the shortest path and identify obstacles without external assistance.

Conversely, AGVs that utilize magnetic tracks follow a pre-installed track to deliver inventory from point A-to-B.

AGVs provide enterprises with a powerful solution to implement innovative intralogistics strategies. Using these systems, the efficiency of diverse material delivery methods may be optimized through automation. Logistics and supply methods such as milk runs, just-in-time deliveries, and A to B delivery systems benefit from the precision and inventory safety automated vehicles offer.

AGVS and AMRs also support the transportation of material handling equipment such as pallets, tugger carts, bins, and racks within the shop floor. Autonomous guided systems are equipped and configured to support the transportation of multiple carts or pallets to meet diverse material handling system’s specifications.

Enhancing Intralogistics Collaboration

An important characteristic of autonomous robots is their ability to collaborate with other systems and human technicians working on the shop floor. This collaborative association is made possible by sensors and triangulation technology. Here sensors and visualization solutions enable autonomous robots to share information with both machines and humans as they navigate the shop floor and triangulation technology ensures human obstacles are avoided.

Sensors and visualization technology attached to autonomous robots can be used both ways – to send and receive information. Thus, making machine-to-machine and machine-to-man communication possible. One benefit of this collaborative process includes the ability to implement the swarm effect.

The swarm effect means that when many robots work together, central navigation systems can ensure the closes robot to inventory picks it up and delivers it in time. This ensures just-in-time deliveries within the shop floor. Autonomous navigation solutions also ensure safety within the shop floor as highlighted in the next paragraphs.

Ensuring Safety with Automation

Material handling equipment that transports heavy equipment or materials has been known to cause accidents on the shop floor. For example, forklifts are known to cause approximately 7,000 accidents annually across the globe and this number does not take into account accidents caused by other material handling equipment such as large pallets or carts. Accident causation factors are generally attributed to incorrect usage alongside intense shop floor traffic and the use of autonomous robots may help reduce accidents.

The navigation sensors integrated into autonomous robots ensure that they can navigate around obstructions including human and inanimate objects on the shopfloor. Hence, when sharing walkways and aisles, AVRs or AMRs can avoid ongoing traffic to reduce accidents. The ability to control AMRs and AGVs using wearables also ensures further protection for workers on the shopfloor in scenarios where autonomous vehicles go rogue.

Implementing Your Industry 4.0 Business Models with Autonomous Robots

The smart factory integrates the use of autonomous systems to speed up manufacturing processes. The ability to automate your material handling requirements means that AMRs and AGVs add smart logistics and distribution management processes to your shopfloor. To take advantage of the many benefits outlined above, developing a functional material handling system is required.

The system includes the fleet of autonomous intelligent vehicles and the software required to manage them. FlexQube offers you turnkey solutions to implement a smart material handling system using autonomous robots.