Automotive supplier orders 115 tugger carts from FlexQube

FlexQube has won an order of 115 tugger carts and three flat shelf tugger carts which will be delivered to an automotive supplier in the fourth quarter of 2019. The order consists of two separate types of tugger carts. The majority of the order (115 carts) is a standard tugger cart designed to help the customer improve the transportation of two types of pallets within their facility. The second cart is a flat shelf tugger cart with four shelves designed to improve the transport of bins, totes, and boxes.

FlexQube was initially contacted to help solve the issue of delivering parts from the warehouse to the assembly line. Jan Brettmann, the FlexQube sales manager involved comments “When we first began the discussions I realized there was a need to improve the delivery of two different types pallets. The flexibility of being able to adjust our tugger carts to two different sizes of pallets was a precious feature to the customer”.

FlexQube was able to come in and create functioning designs that were ideal to what the customer needed. After testing a tugger cart, the customer decided to go ahead with FlexQube as their supplier. In the end, the deciding factors were the ability to alter the carts based on the materials and the strength of the carts.

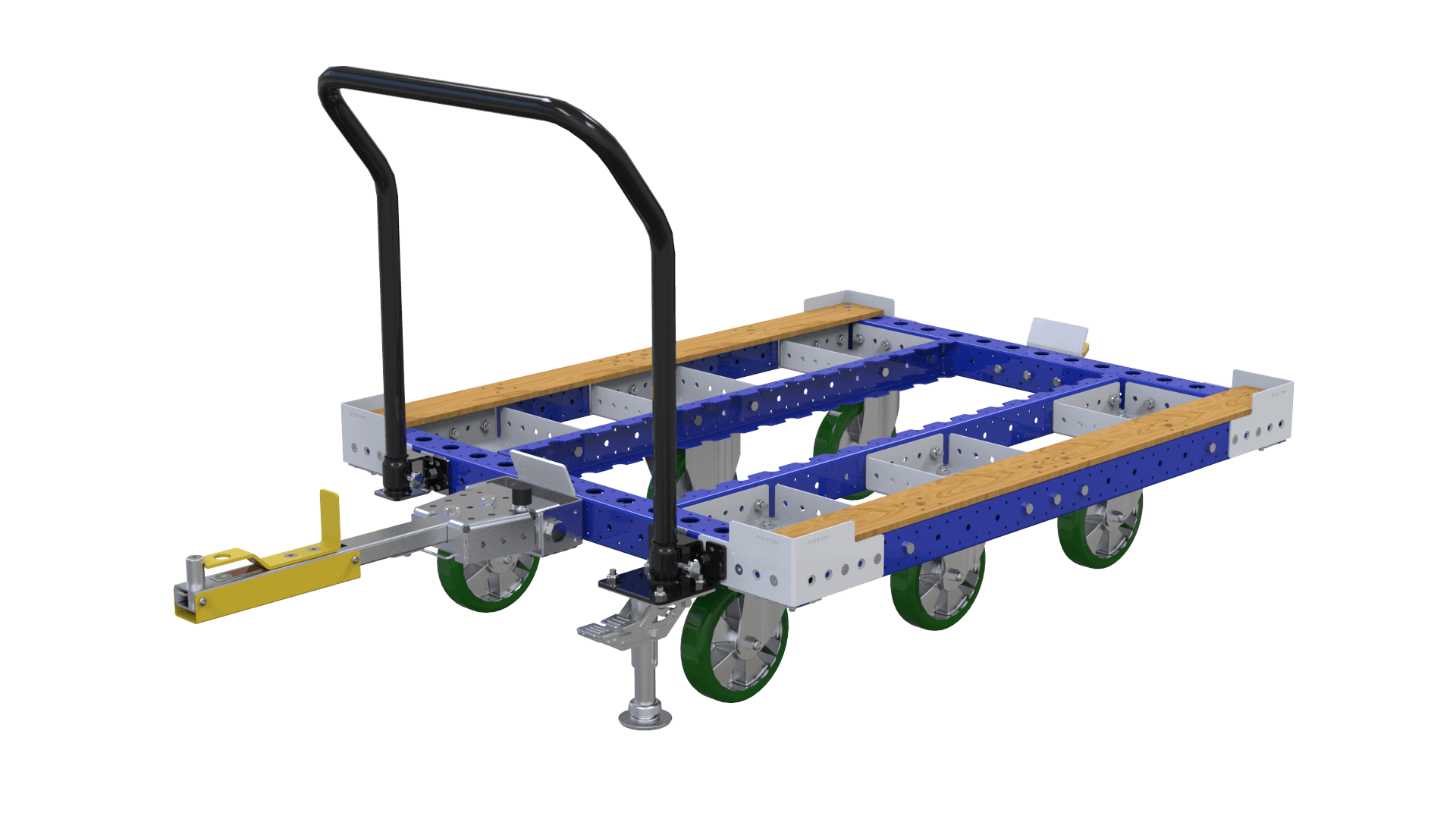

The 115 pallet tugger carts were designed with pieces of wood which were added to ensure the carts can then hold two separate pallet sizes. The tugger carts can transport EUR 1200 x 800mm in the middle, and an industry sized pallet the 1200 x 1000mm on top.

The 3 flat shelf carts were also ordered to improve the delivery of smaller components in bins, totes, and boxes. The height of these shelves can be easily adjusted, which was an added feature for the customers because it means the carts were not locked into fixed heights.

The carts

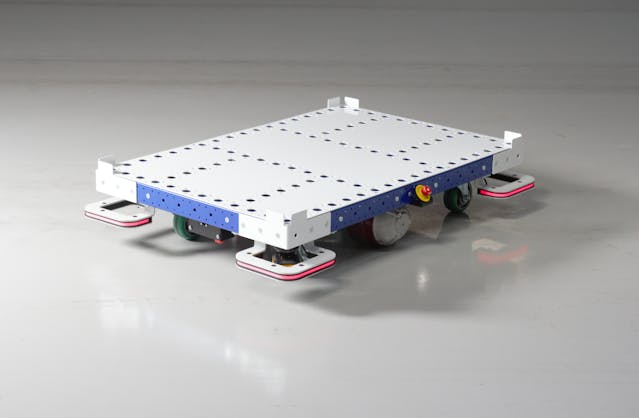

Flat Shelf Cart – 840 x 1400 mm

Q-100-3109

This flat shelf cart is designed to improve the process of delivering different bins, boxes, and totes to the assembly line. This cart comes with a foot release tow bar to improve ergonomics for the operator and allows the cart to be transported via a tugger train system. The height of the shelves can be easily adjusted to match the height of your materials.

Tugger Cart – 1050 x 1260 mm

Q-100-3108

The automotive supplier ordered 3 of the above tugger carts, to improve the process of materials being delivered from the warehouse. With these tugger carts, two small pieces of wood were used to help the cart hold two different sizes of pallets. The EUR pallet 1200 x 800mm in the middle of the cart & 1200 x 1000mm on the top.