AGV vs. AMR – which solution fits your business?

Introduction to AGV and AMR

In the race toward smarter productions, automation has become a must-have for boosting efficiency. Two of the most common solutions in that field are, without a doubt, Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs).

These systems have evolved from simple guided carts into sophisticated robotics and automation platforms. They are crucial in modern logistics, mainly because a larger share of businesses require flexibility, speed and cost‑efficiency in material flows. These solutions can relieve staff from repetitive transfers, improve ergonomic conditions, boost throughput and create a foundation for Industry 4.0‑ready operations.

AGV – Automated Guided Vehicles

An AGV is a mobile vehicle that follows a predefined guide path (such as tape, wires in the floor, magnetic strips or reflective markings) to move material from point A to point B in a warehouse or manufacturing facility.

AGVs are typically used for transporting pallets, heavy loads, or towing carts in fixed workflows, such as repetitive supply‑to‑line operations in automotive manufacturing or large, stable warehouses.

AMR – Autonomous Mobile Robots

AMRs bring a flexible and intelligent twist to mobile logistics. Rather than following wires or magnetic strips, they navigate on their own by using sensors, cameras, laser scanners to map their surroundings.

Through this technology, the robots can sense obstacles and keep operating with minimal setup. Some common use cases for AMRs are busy fulfillment hubs, dynamic manufacturing floors, multi‑carrier setups, and other spaces that depend on agility.

AGV vs. AMR – what’s the difference?

Technology and navigation methods

As described above, AGVs rely on pre‑set paths to operate, which keeps their movement stable and predictable within the factory or warehouse. AMRs, on the other hand, use built‑in intelligence to navigate and adjust automatically to what’s happening around them.

Flexibility and scalability

Given the technological differences, AGVs are highly functional within existing layouts, when the process is stable, while AMRs are more fitting in environments where material flows and layouts require frequent adjustment. Their modular architecture makes them future-proof and easy to scale.

Safety and workplace environment

Both systems aim to cut down manual work and make the workplace a safer environment. AGVs lower the risk of accidents and support ergonomic transport, while AMRs take it a step further by mapping, scanning, and reacting to their surroundings in real time.

Which system is better for warehouse automation?

This depends entirely on how your warehouse operates.

If your processes are steady, routes stay the same, and things don’t change much from day to day, an AGV is probably the right choice. It’s quick to install – you can have it running in about an hour – and you don’t need to modify your existing setup.

If your operation is more fast-moving – maybe the layout shifts often, routes change, or you handle different types of loads – then an AMR might be a better fit. Its one-robot/multi-carrier concept gives you the flexibility to constantly adapt as your business grows.

AGV vs. AMR price: Cost comparison

Purchase cost vs. operating cost

AGVs make automation simple and low-cost. They don’t require Wi-Fi, fleet management software, or any big infrastructure changes. Just set it up, and it starts working. This is a great option if you want to automate quickly without locking up your budget on a more complex solution.

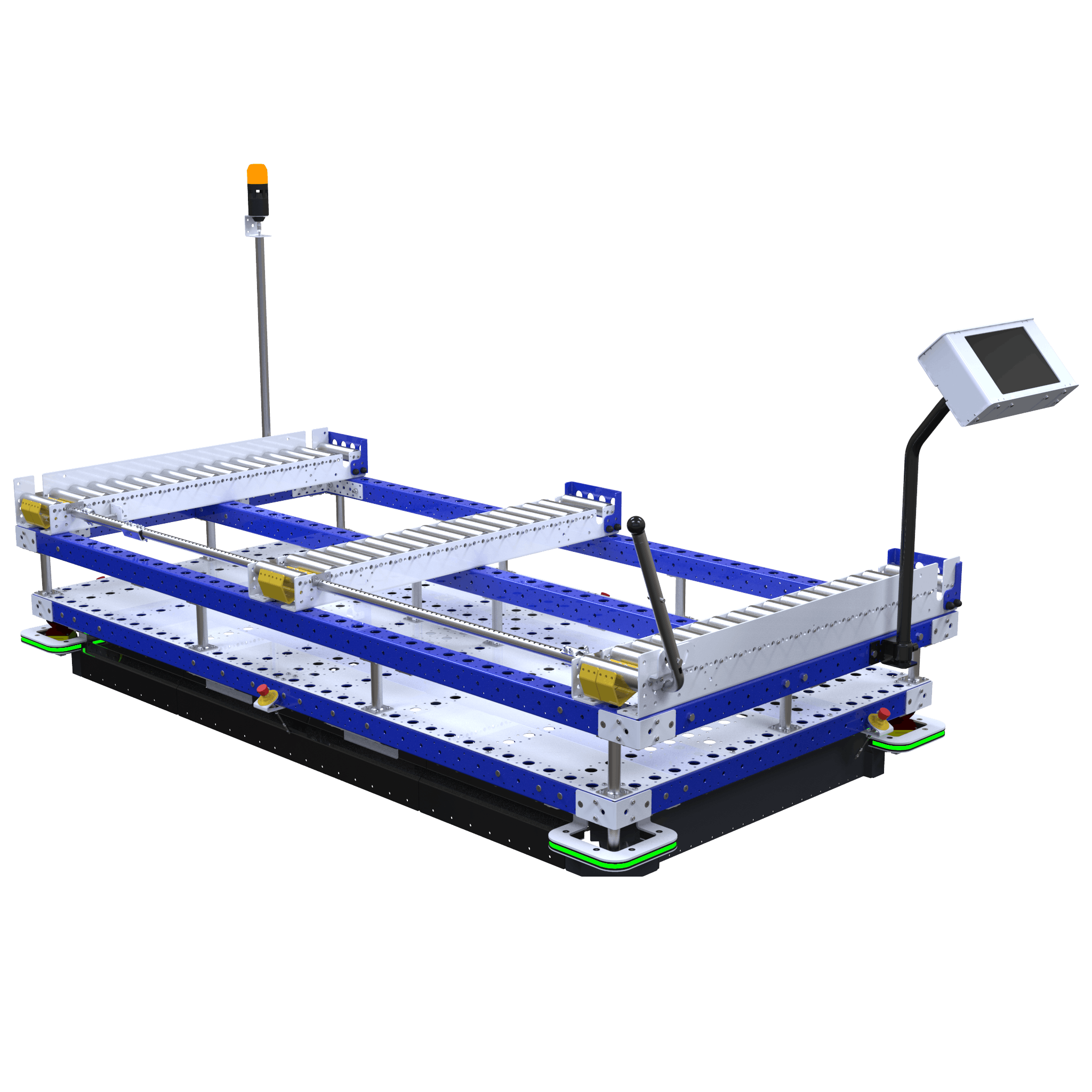

AMRs are a bigger upfront investment. They include the robot, modular carriers, and integrated software, which makes them fit complex setups. The advantage is flexibility: you can scale, reconfigure, and tweak your operations without ripping out equipment or rewiring your facility. FlexQube stands out here: the Navigator AMR is compatible with all load carriers, which means expanding your setup doesn’t require extra robots.

ROI and total cost of ownership

AGVs often deliver ROI in 6–12 months, especially in repetitive workflows where uptime and payload matter most. AMRs can reach ROI in under two years. However, their flexibility pays off over time; you can add carriers, remap routes, and adjust layouts without starting from scratch.

AGV and AMR in the future of logistics

The future of logistics is characterized by adaptability, connectivity, and intelligent design, just like the FlexQube AMR System. Modular and scalable structures are replacing rigid, one-size-fits-all setups to help manufacturers and warehouses to evolve without costly rebuilds.

When combined, AGVs and AMRs create a powerful foundation for scalable automation. They optimize internal logistics, enhance worker safety, and make it possible to respond quickly to shifts in production or demand. With FlexQube, you’re ready to harness this next wave of intelligent automation and build a logistics system that grows with your needs.

AGV or AMR: A quick recap

Still not sure which option is the right fit for your operations? Here’s a short rundown of the main points to help you make the best choice.

- Small vs. large facilities: AGVs are great for smaller facilities with predictable material flows, while AMRs scale better in larger or multi-building operations.

- Simple vs. complex layouts: AGVs work best in straight, consistent workflows, while AMRs excel in spaces that change frequently and need adaptability.

- Standardization vs. flexibility: AGVs suit standardized processes, while AMRs thrive in environments where every load, route, or task might differ day to day.