Material Handling Carts Make Production Easier!

Have you ever taken a moment to think about the massive amount of coordination, precision, and strength that are necessary to move the various materials used in your production facility? It’s a lot. But the right Material Handling Equipment can make those processes more straightforward and easier. In fact, customized material handling equipment can be utilized throughout your facility to assist in the delivery of various parts and components to your assembly line workers right at the point of assembly.

These line-side material handling solutions are increasingly popular and are an integral part of a Flexible Material Handling System which can provide a wide range of benefits to a company. Today, we wanted to specifically look at four key ways that Material Handling Carts can make production easier. But first, what is a material handling cart?

Click here to see all of our material handling carts

What is a Material Handling Cart?

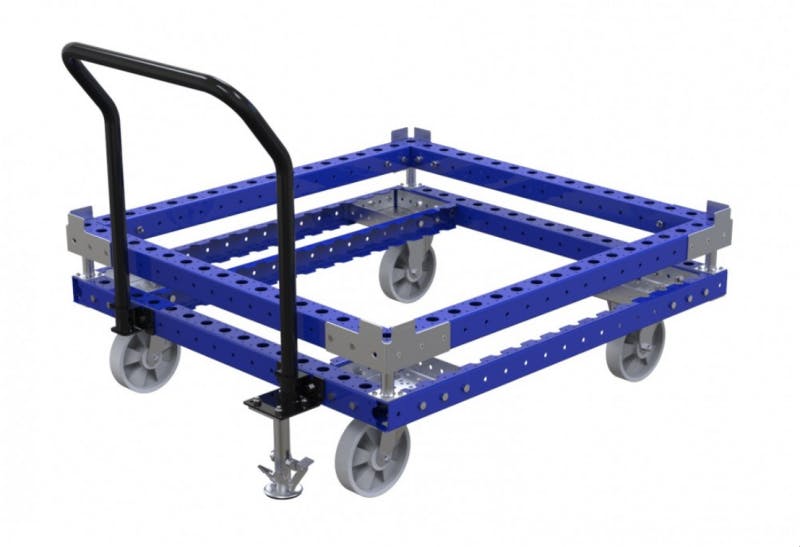

A material handling cart is a form of equipment used to help transport materials. Material handling carts help with transporting materials internally through a factory, facility, or warehouse. The basic cart is a pallet or flatbed cart that is used for transporting large and heavy pallets and containers. These carts are usually equipped with wheels (casters) and a handlebar for the operator to push manually. But material handling carts can also come in a wide variety, here at FlexQube we encourage our customers to customize their carts for their materials. So this means, using different carts such as hanging carts, kit-carts, shelf carts, rotating carts, or carts with rollers.

1. Facilitate Better Work Flow and Shorter Production Times

Material handling carts can be used for a variety of purposes throughout the production process, including line-side delivery of raw materials or kitted parts and the transportation of in-production or completed products. By implementing custom solutions that perfectly fit your production needs, your facility’s workflow can be simplified and improved. And when your employees have the right materials at the correct times, your production times improve as well.

2. Minimize Downtime Caused by Parts Collection

It’s a simple fact that if parts aren’t immediately accessible, it takes time to collect them. When this occurs, it inevitably leads to production downtime. By incorporating line-side material handling carts into your production process, you can minimize this downtime by having the parts readily available when and where they are needed.

3. Allow Skilled Laborers to Focus on High-Value Activities

Pretty much every production process requires highly skilled people who are trained to perform specific tasks. By utilizing custom material handling carts to put needed parts within easy reach, these skilled laborers are able to spend less time finding and collecting parts and more time on their specialized tasks. As a direct result, production times will drop, and production outputs will go up.

4. Utilize Factory Floor Space More Efficiently

When correctly designed, custom material handling carts can simultaneously provide storage and transportation. This allows you to utilize your limited space in much more efficient ways than would be otherwise possible. For example, there is no need for large empty areas to be used by forklifts or other bulky transportation equipment. As an added bonus, there is also little or no need to invest in additional storage and transportation equipment.

Conclusion:

In short, the implementation of the right material handling equipment can improve your bottom line, increase productivity, and allow workers to focus on their assigned production activities. The best equipment is also designed with safety and ergonomics in mind to help reduce worker injuries. Using material handling carts can bring alot to the table when you are looking at improving your internal workflows. The benefits of freeing up time for different employee’s, taking advtange of your workspace more effectively, and minimizing your downtime can vastly improve the processes within your factory, facility or warehouse. Making the transition from old-style material handling practices towards newer (and in most cases cheaper) equipment can make the world of difference for your results.

Here at FlexQube, we can help you create the perfect solution for your specific production needs.

If you’re ready to create your custom material handling system, Contact FlexQube Today!

You may also like:

A guide to the basics of successful material handling