Heavy Truck Manufacturer

Automating Transport of Seats and Doors to Cab Assembly Line.

Challenge

The customer needed to reduce forklift traffic near the assembly line and efficiently transport diverse materials of varying sizes. High product variation and limited line-side storage required pre-kitting and precise delivery. Seats and doors were assembled using a two-bin system, with forklifts replenishing racks every 10 minutes, adding complexity and safety risks.

Achievement

Solution

5 Reasons to Automate.

The main challenges in this situation can be summarized as:

- High product variation – many different cab sizes, colors, and options increase complexity in sequencing and material delivery.

- Complex material handling – large number of parts must arrive in the right order and within easy reach of assemblers.

- Limited line-side storage – forcing reliance on pre-kitting from suppliers or internal picking areas.

- Frequent replenishment needs – seats and doors require constant refilling every ~10 minutes.

- Manual forklift dependency – drivers must track rack levels, transport, and replace them, making the process labor-intensive and prone to inefficiency.

A NEED FOR FORKLIFT ALTERNATIVES.

One of the main reasons this company looked to FlexQube was the need to find forklift alternatives. Manufacturing is the most common industry for forklift fatalities, representing 42% of all deaths. According to statistics, there are 35,000 – 62,000 injuries and around 90 fatal accidents yearly, caused by the use of forklifts. Despite this, forklifts remain the most common way to move large, heavy racks from warehouse to assembly lines, since tugger trains pose ergonomic challenges where operators must manually move loaded carts from the train to the point of use. Thus, the project scope included replacing the forklifts used in the assembly line with an automated system.

One of the main reasons this company looked to FlexQube was the need to find forklift alternatives. Manufacturing is the most common industry for forklift fatalities, representing 42% of all deaths. According to statistics, there are 35,000 – 62,000 injuries and around 90 fatal accidents yearly, caused by the use of forklifts. Despite this, forklifts remain the most common way to move large, heavy racks from warehouse to assembly lines, since tugger trains pose ergonomic challenges where operators must manually move loaded carts from the train to the point of use. Thus, the project scope included replacing the forklifts used in the assembly line with an automated system.

AUTOMATED TRANSPORT SOLUTION.

With the innovative and patented Navigator AMR system, FlexQube can offer the customer an automated transport solution to move

material racks with different size, shape and weight. One small and standardized robot can, through a standardized coupling, navigate modular and motorized Load Carriers that, in this project, were customized for the seat and door racks.

MAIN PROCESS - HOW IT WORKS.

① Assembler push button to start mission.

② AMR pick up Load Carrier with empty rack.

③ AMR move Load Carrier to warehouse.

④ AMR drop off Load Carrier with empty rack.

⑤ AMR pick up Load Carrier with full rack.

⑥ AMR transport full rack to assembly line.

⑦ AMR goes to home/charging station.

KEY BENEFITS.

CLEAR ROI

ROI between 1 and 3 years depending on the number of shifts.

OPERATONAL SAVINGS

$68k savings per year for each forklift replaced.

OUTSTANDING SAFETY

A unique, patented PLd-rated feature that identifies Load Carrier size on the fly and automatically adapts the AMR’s safety fields.

SMALL FOOTPRINT & HIGH FLEXIBILITY

Using one small AMR with standard coupling that can move any size of Load Carrier.

FlexQube AMR System

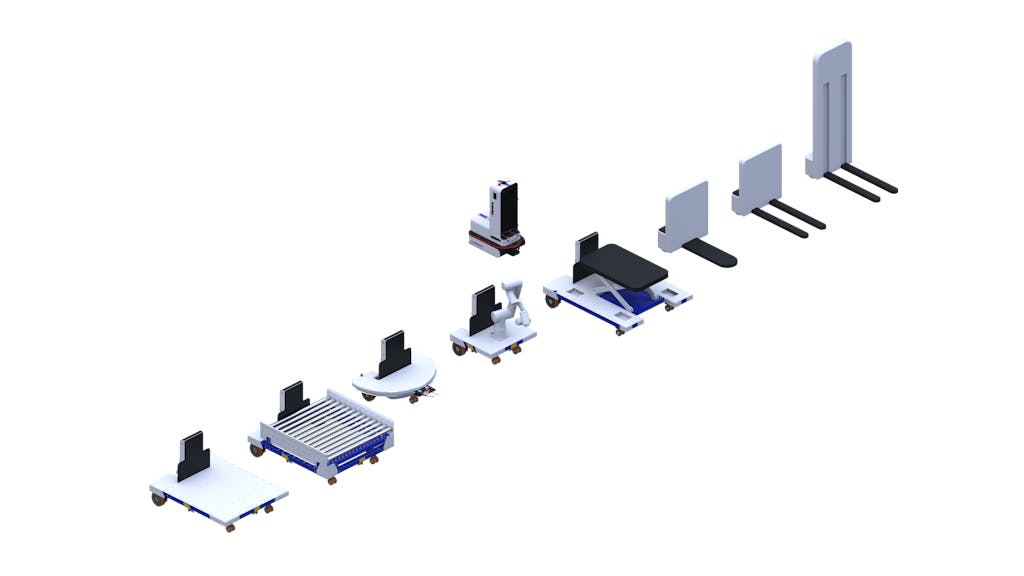

LOAD CARRIER SOLUTIONS.

The unique FlexQube AMR System is based on a modular “one robot/multi-carrier” concept. Perfect for complex manufacturing environments, the AMR itself is a non-load carrying system, equipped with safety system, navigation system and battery. This robot can couple with FlexQube’s wide range of motorized Load Carriers through a standardized coupling interface, transferring power and data to the Load Carrier motors in order to navigate it.

FlexQube AMR System

WIRELESS CHARGING SYSTEM.

A key requirement for FlexQube was to ensure continuous robot operation without downtime or disruption to production. By integrating Wiferion’s wireless charging technology via the WCPS infrastructure delivered by Pohlcon, FlexQube enabled fully contactless charging directly at key process stations. The robots automatically charge during normal stops for loading and unloading, eliminating the need for manual connectors, separate charging areas, or additional floor space. This in-process charging approach ensures the fleet remains fully operational at all times, supporting high-throughput, 24/7 production environments.