Modulare und motorisierte Wagen mit schneller Implementierung.

Entstanden aus der Idee, unsere Kunden zu Weltmarktführern in der Intralogistik zu machen und unserem unermüdlichen Streben nach Innovation und dem Herausfordern der traditionellen und nicht nachhaltigen Art der Materialhandhabung – haben wir das FlexQube AGV-System entwickelt. Ein einzigartiges AGV, das so konzipiert ist, dass es Ihnen, Ihren Prozessen und Ihren Anwendern gerecht wird, ohne Ihre bestehende Infrastruktur oder Materialhandhabungsflotte ändern zu müssen. Ohne den AGV-Frust. Und für Ihre sich ständig ändernden Bedürfnisse.

DESIGNS

UNBEGRENZTE INDIVIDUELLE VARIANTEN

GRÖSSE

JEDE GRÖSSE UND FORM, DIE SIE BRAUCHEN

IMPLEMENTIERUNG

BETRIEBSBEREIT IN CA. 60 MINUTEN

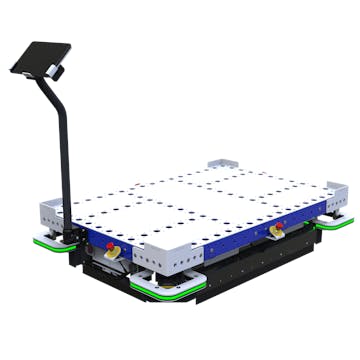

FLEXQUBE AGV SYSTEM

Die Zukunft der Automatisierung ist einfach.

Indem wir das ursprüngliche FlexQube-Konzept beibehalten und es mit intelligenten Modulen ergänzen, können wir ein flexibles, erschwingliches und benutzerfreundliches Automatisierungskonzept anbieten. Das bedeutet, dass Sie bei Ihren Anforderungen keine Kompromisse eingehen müssen. Entwerfen Sie Ihr ultimatives AGV basierend auf Ihren Prozessen, Bedienern, Materialien und Einrichtungen. Finden Sie Ihre perfekte Lösung, garantiert durch unser modulares Konzept.

Verpasst nie eine Schicht.

EINSATZZEIT

8h

BATTERIE

wechsel

TECHNISCHE EIGENSCHAFTEN .

NAVIGATION

Kamera/Optisch.

GESCHWINDIGKEIT

1 m/s.

LADUNG

1000 kg .

ZUGKRAFT

2000 kg .

NAVIGATION

Liniengeführt.

Klebeband oder Lackiert

SICHERHEIT

Hokuyo Laser Scanner.

Generiert eine 360° Rundumsicht ohne Blindstellen

PLATZIERUNGSGENAUIGKEIT

± 1 cm.

Q-100-7100

Roller AGV - 1260 x 840 mm

Product

Q-100-6903

Palette AGV – 1260 x 1050 mm

Product

Q-100-6907

Palette AGV – 1260 x 840 mm

Product

Q-100-6748

Regal AGV – 910 x 840 mm

Product

Q-100-6353

Roller AGV – 1260 x 1260 mm

Product

Q-100-6696

Anhängepalette AGV – 910 x 840 mm

Product

Q-100-6321

Palette AGV – 2520 x 1260 mm

Product

Q-100-6354

Palette AGV – 910 x 840 mm

Product

Q-100-6385

Roller AGV – 1260 x 1260 mm

Product