The 6 Most Common Questions about the AGV System

Automation within manufacturing, distribution, and warehouses continues to take steps forward. FlexQube has stepped up our original concept by adding smart and motorized building blocks to our existing modular system. This has led to the introduction of the AGV to the material flow and handling market. The AGV was born out of the idea of improving simple material flows and routes by automating them with a motorized cart. Originally, automation has been linked to having an automated robot pulling non-automated trolleys holding the material behind it. The AGV has looked at merging these two ideas together.

But no matter how simple the automation process or concept is, there are always important questions to answer throughout the automation journey. Below we have outlined six of our most common questions about the AGV.

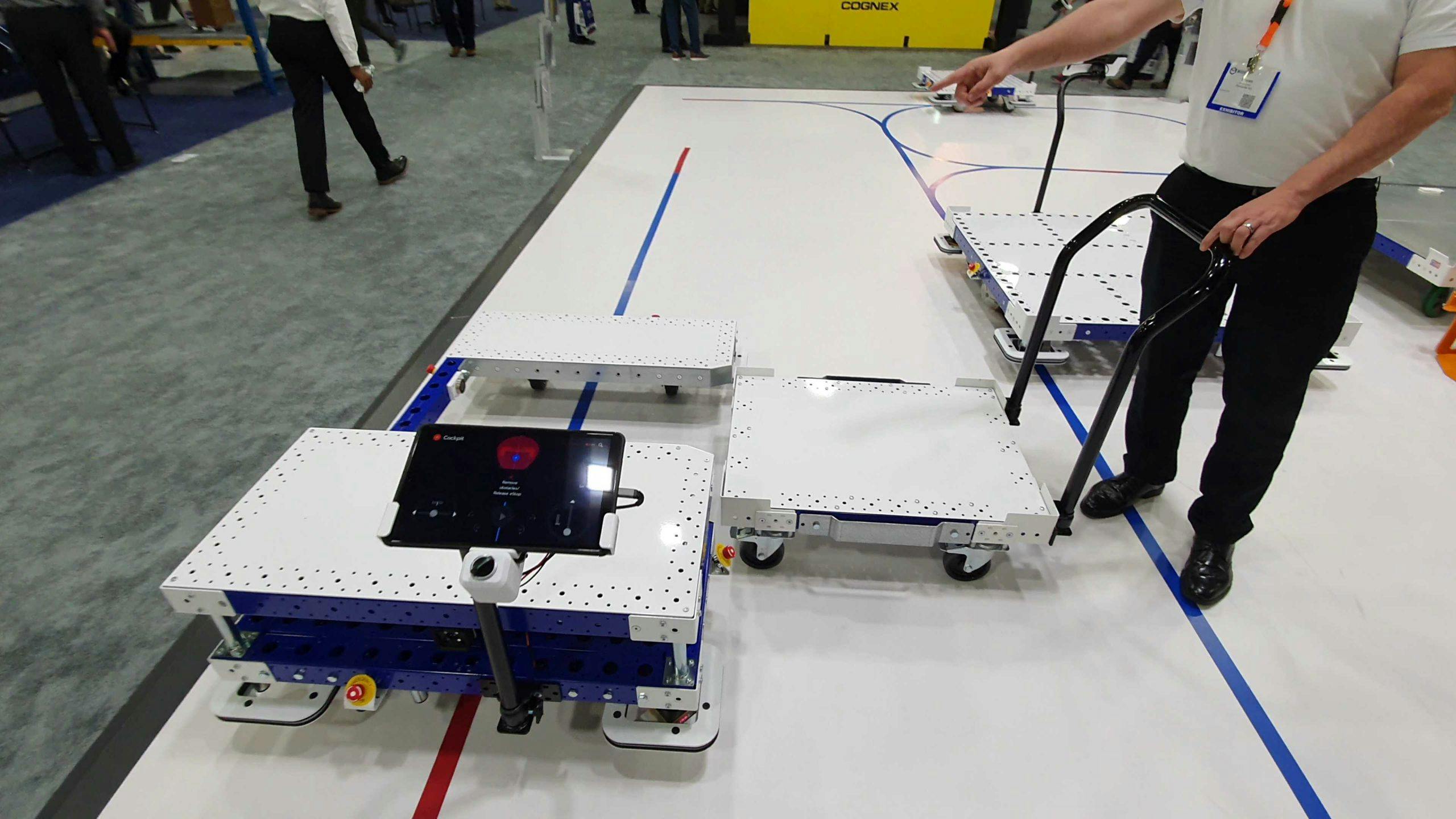

Is it a magnetic line that the AGV follows?

No. The AGV has been developed to be as simple and user friendly as possible. Therefore, the line is just a regular colored tape. This keeps the implementation costs down, cuts the time needed, and makes the overall process as simple as it should be. In most cases, depending on the length of the route, the AGV can be up and running within the hour. This makes route testing and course changing that much easier when your internal material flows change.

Does it have to be the same color tape every time?

No. The AGV can follow any line that provides a contrast to the floor it is driving on. On top of this, the line doesn’t have to be created using tape, and it could also be a painted line on your shop floor. The AGV comes with two cameras to track along the lines ensuring that the tracking accuracy is high. We have had customers use any tape color from blue, red, yellow, and white. You can select the color of the line you would like the AGV to follow.

Want to stay up to date? Subscribe to our newsletter

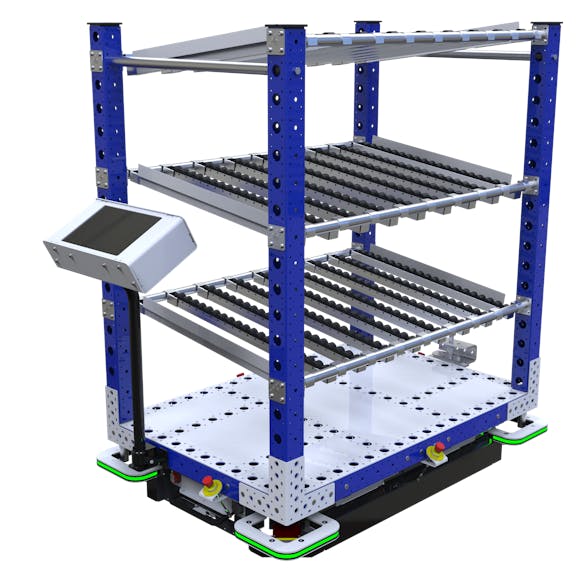

Does the weight capacity change with a different size of AGV?

No. The AGV is a robust and modular system with the base frames varying from a minimum size of 910 x 840 mm to a maximum capacity of 2510 x 2510 mm. No matter where your AGV falls on this size spectrum, it can be loaded with up to 1000kg. This makes it much easier to move heavy loads, especially if you have narrow aisles because many of the AMR’s and AGV’s on the market come in larger standard sizes for heavier payloads. This can put pressure on distribution warehouses & manufacturing that have a limited amount of space.

What type of scanners is the AGV equipped with?

Our AGVs are equipped with Hokuyo safety scanners. These scanners are designed to be used as a safety tool for the AGV and are not used for navigation. There are two scanners equipped to each AGV, one in each opposing corner. The scanners have a 5 meter and 270-degree protection zone, with two scanners it creates a 5-meter 360-degree field around the AGV. On top of the 5-meter protection zone, it has two warning zones, which begin up to 20 meters away from the AGV.

How do you determine the ROI?

At FlexQube, we determine the ROI using metrics based on each individual case. We work towards showing each customer the money saved in each business case. To resolve this, we would look at the length and time it takes to complete each route, the number of transports needed when using existing transport methods, and then compare these measurements to the cost of using the AGV.

How long is the implementation time?

To implement the AGV, it is generally quite short. It comes down to different factors such as the length of the route and the number of stations that are needed along each route. Generally, most AGV routes can be set-up and mapped within 2 hours. It also helps that infrastructure such as Wi-Fi systems, or magnetic strips are not needed for the AGV to be implemented.

If you would like to learn more about the AGV you are more than welcome to view one of our previous webinars or sign up for a future webinar to learn more about FlexQube’s flexible automation concept.