The Top 10 suggested Lean Tools

The Top 10 suggested Lean Tools

Learn about the top lean manufacturing tools. Lean manufacturing and its principles are critical guidelines for manufacturing facilities globally.

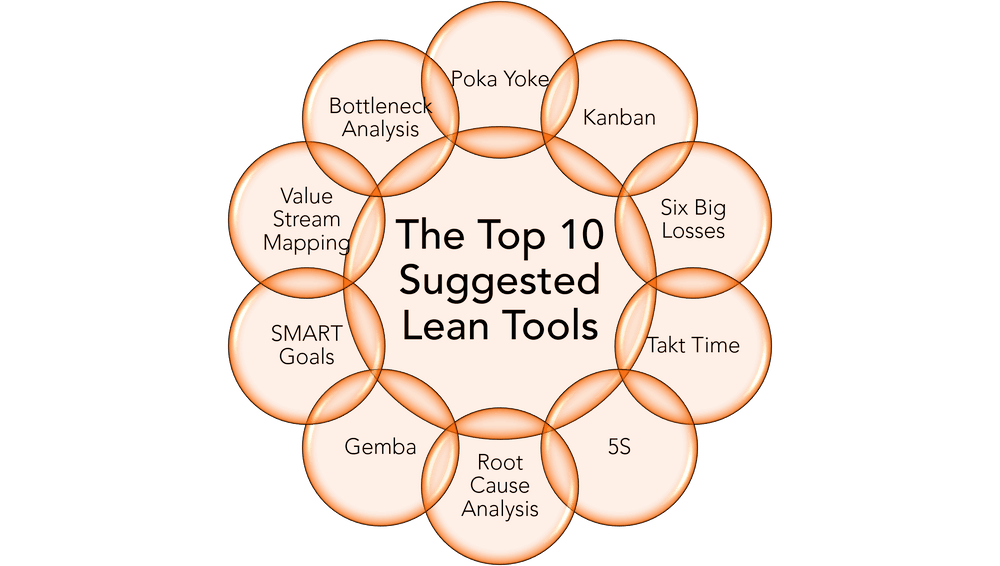

Within the principles of lean, you can implement specific tools at different times to counteract various problems. We have discussed a number of these tools in earlier blog posts, such as the PDCA cycle and Jidoka methodology. But in this post, we will provide short summaries of 10 of our suggested lean tools for you to implement. The list of lean tools we will summarise are:

- Poka Yoke

- Kanban

- Six Big Losses

- Takt Time

- 5S

- Root Cause Analysis

- Gemba

- SMART Goals

- Value Stream Mapping

- Bottleneck Analysis

Poka-Yoke

Poka-Yoke is about finding mistakes and making sure they don’t continue in the manufacturing process. The goal of Poka Yoke is to achieve a zero-defection rate throughout the production line. Japan initially coined it and it initially came about as fool proofing, but later it evolved into mistake-proofing. Poka-Yoke helps save time and money by reducing faulty products in the manufacturing line.

Kanban

Kanban is a card system that helps organize the flow of goods in a manufacturing facility using signboards or visual boards. Kanban began in the 1940s as an easy to use planning system within the Toyota automotive.

Kanban helps demonstrating the actual process of materials. It is used as a “pull system” that signals when more goods are required. This can help bottlenecks in the manufacturing line as well as help to prevent the oversupply of certain materials.

Six Big Losses

The six big losses are six different areas of productivity and efficiency loss. It’s a useful method for identifying where the significant losses come from and guidelines on how to eliminate the waste. The six big losses are:

- Unplanned stops

- Planned Stops

- Small stops or idling

- Speed or slow cycles

- Production Defects

- Startup Losses

Takt Time

Takt time is a lean methodology tool that refers to the speed at which a company can make and deliver a finished product to a customer. We also refer to it as production speed, and it enables us to comprehend our daily manufacturing requirements.

To find the Takt time (https://kanbanize.com/continuous-flow/takt-time), divide the available work time in a day by the customer demand for a specific product.

For example, if there are 420 work minutes per day and the customers demand 30 finished products per day. Then the takt time is 420/30 = 14 minutes. This means that we need to finish a product every 14 minutes to keep up with the demand.

5S

5S is a lean toolset for organizing different workspaces, so they are prepared for optimal work safety and capacity. Its main goal is to organize and clean the workspace by placing tools, materials, and items in their proper positions. The 5s systems include the following steps:

- Sort

- Set in Order

- Shine

- Standardize

- Sustain

These five necessary steps help to eliminate waste within manufacturing that can be produced from unorganized workspaces.

Root Cause Analysis

Root Cause Analysis is a method for finding the main cause of a problem. Stopping production when something is wrong, then investigating it, is a good way to learn why it happened. One of the most common forms of finding the root cause of a problem is the five why approach. This involves asking why five times to reach why the problem occurred.

Gemba

Gemba means “actual place” in Japanese and it refers to leaving your desk and going to the real location. People use Gemba to solve problems or work on improvement projects. This helps in ensuring that the problem solving or improvements that you are planning will work in reality.

SMART Goals

Many businesses and departments use SMART goals, which demonstrates the method’s usefulness. SMART stands for:

- Specific

- Measurable

- Attainable

- Relevant

- Time-Specific

This can help in planning and strategizing plans to help make goals more effective.

Value-Stream Mapping

Value stream mapping is a tool for helping to map out the flow of the production process. This is beneficial for seeing a top-down perspective of the flow of your materials in your production line. Using this tool can help you find delays in the process, to increase efficiency in certain areas. The team utilizes an initial value stream map to plan future production improvements and identify areas where they can reduce waste.

Bottleneck Analysis

We utilize the Bottleneck Analysis tool to identify areas in the process that restrict efficiency. Manufacturers use this manufacturing tool to identify the areas that require focus to improve the throughput of the manufacturing line. Improving areas where there is a bottleneck can lead to improved output in other areas of the process.

We have outlined short summaries of the ten lean tools that we think could be beneficial for your manufacturing line. Choose one or two actions that can significantly impact your production line. Starting with all ten at once could have negative long-term effects, so it’s better to do one at a time.