Improving Warehouse & Factory Logistics With Optimised Part Picking

In manufacturing, warehousing, and retail chains, inventory shrinkage has been highlighted as one of the major causes of downtime and defects to materials used in production. Inventory shrinkage refers to the number of goods that do not make it to their expected endpoint. In manufacturing and warehousing, this endpoint can be either workstations or organised drop-off locations while in retail the customer is generally the endpoint.

Statistics show that Inventory shrinkage or loss is a symptom of extensive logistics challenges facilities face with managing their part picking procedures. A poorly defined picking process will lead to downtime, material waste which are by-products of inventory shrinkage. In this article, improving factory logistics and eliminating waste through efficient part picking will be discussed. The article will cover:

- What is Part Picking?

- How to improve picking efficiency.

- How picking errors can be reduced with proper material handling procedures.

What is Part Picking and Where is it Used?

Part picking is an integral activity that is carried out in every manufacturing operation and warehousing facilities. It involves the picking and transporting of an item or material that has a role to play in the production of a larger product. The part picking process generally occurs in multiple locations on the shop floor and plays a role in ensuring manufacturers meet their production goals. This is because successfully transporting the part to its drop-off point provides floor technicians with the items needed to complete manufacturing activities.

An example of how part picking occurs is in the manufacturing of discrete goods. In this situation, production materials must be picked from warehouse storage and transferred to workstations. Once the materials are depleted, a worker must pick more materials and transfer them to the workstation to ensure production continues.

The Challenges and Effects of Inadequate Part Picking Systems

Although part picking is termed as non-value added process since it is not a direct part of the production cycle, a poor picking system has its negative consequences. The challenges facilities face in handling part picking includes:

Locating Items on the Shop Floor

Tracking hundreds of items or materials on the shop floor can prove to be a challenge for some facilities. With a poor inventory system and navigation coordinates, locating these items and picking them will be challenging.

The Store Environment and Navigation Routes

An inadequate picking process that does not provide enough space for the picking of items will lead to waste. Another important challenge is poorly designed routing strategies for transporting items to delivery points.

Inadequate Material Handling Equipment

The transportation of picked items is also an important process in part picking. In many warehouses, manual solutions are still being used and this could prove challenging.

Optimising Warehouse Logistics with Adequate Part Picking Strategies

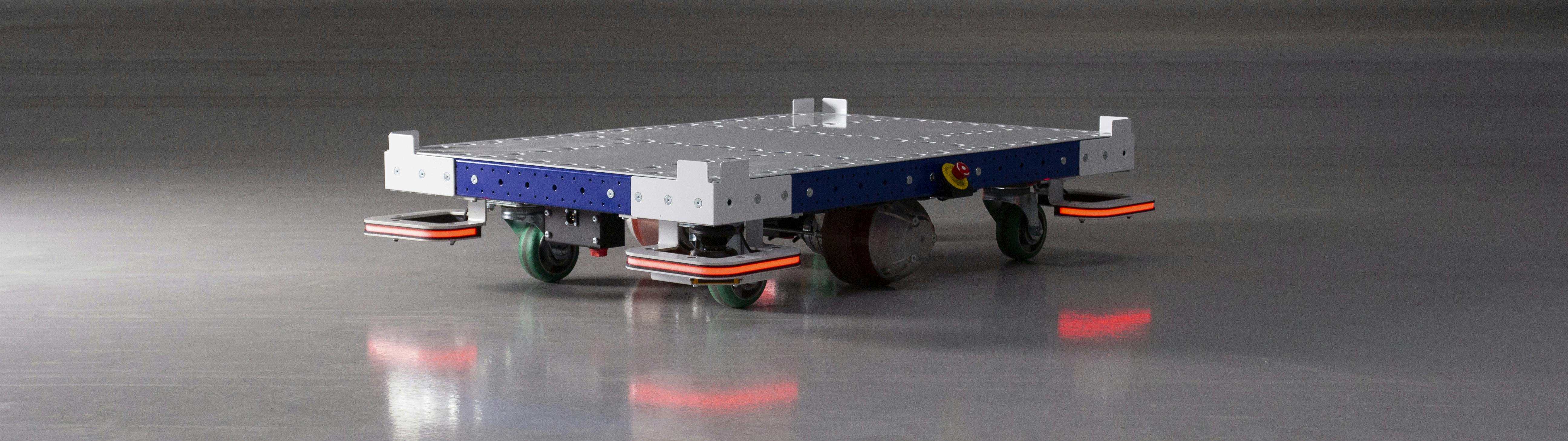

Dealing with the challenges warehouses face in terms of logistics, a practical suite of solutions that is cost-effective is needed. And this is where developing an optimal part picking strategy comes into play. Today the option of automating the picking process remains the best solution to dealing with logistical challenges. Therefore, integrating a technological framework that monitors the picking process through route visualisation, automated guided vehicles, carts, and alerting systems is the way forward.

To successfully implement an automated part picking strategy driving by technology, the following considerations must be made:

How orders can be accurately tracked

The orders coming from the shop floor or workstations drive the picking process. Therefore, the first step to sanitising picking logistics is creating a centralised ordering system where order tickets are logged and managed. Here, and industrial cloud-based solutions can be used to develop a functional monitoring system for orders.

How walking times can be reduced

If the shop floor is filled with workers walking around to fulfill orders this is a sign that your part picking system has failed. The goal is to limit the number of workers on aisles to reduce confusion. Here, tugger train systems and automated guided vehicles should be used to transport materials to their end-point. These systems have the advantage of pulling multiple carts which will meet more requests.

How the margins of errors can be reduced

The use of manual labor to handle counting, categorising and storing materials without support leads to confusion. This is why a visual system has been recommended by experts to aid the part picking process. Here, RFID tags or bar codes can be assigned to materials which ensure that every item shows up on your monitoring systems. This will make lost inventory a thing of the past.

Determining The Way Forward…

The integration of automation and technology in warehouses and shop floors is the best solution for dealing with warehouse operational logistics relating to part picking. You can start automating your part picking process by analysing your material handling system and the equipment used. This will speed up picking times and the delivery process.