How FlexQube prevents Icebergs from melting

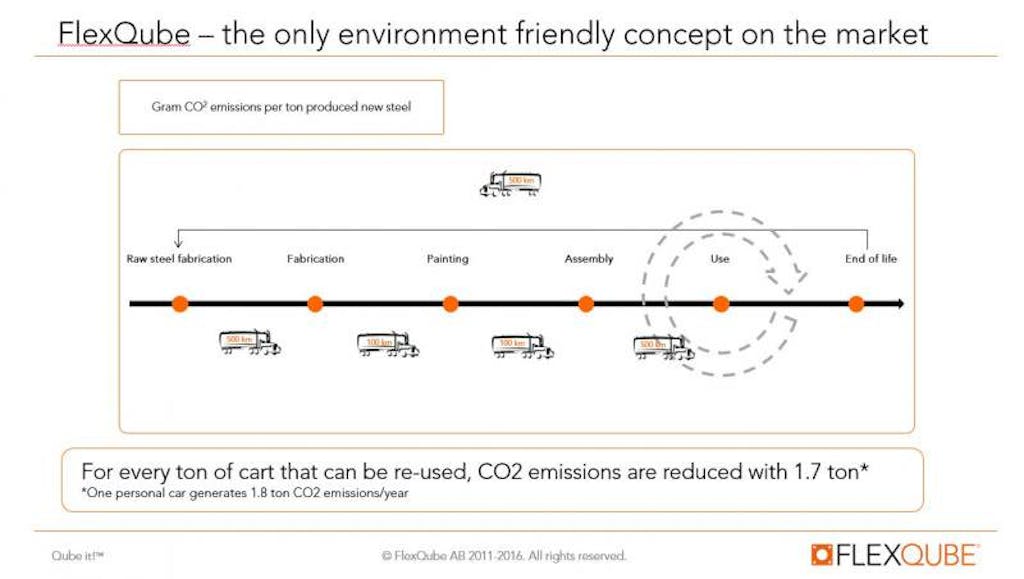

With FlexQube products we have tried to take energy reduction & optimization of lean processing to the next level. The core concept behind the FlexQube products is that your solutions can be re-built, based on the revolutionary fact that our products are bolted together rather than welded.

We are single handedly helping manufacturers re-create their carts/material handling equipment with their existing FlexQube products. As an example, this means that your original order of 48×45 inch Flatbed Carts can then be re-built using the same parts (with a few small additions) into a shelving rack, or a flat shelf cart.

This cuts out the process of placing a new order with your local welding company and having to sit through the sales process/design process again. It also saves you from scraping your original order of 48×45 inch tugger carts (not so environmentally friendly), then using more steel and resources to weld together your next shelving rack or flat shelf cart. In addition to this a recent study made by one of our customers showed that FlexQube carts were 40% less heavy than competitors carts meaning a further reduction in steel consumption for the same applications.

With the FlexQube concept your next order of material handling equipment could be just 1 shipment of a few extra FlexQube components or a new design session with one of our engineers.

We recently conducted a study that using the FlexQube concept and reconfiguring 200 flatbed carts saves the same amount of CO2 emissions as driving 10 cars for a whole year. Converting that to metric tonnes of melting arctic ice-bergs that is actually as much as 250 tonnes of ice! 200 FlexQube carts in this design contains 50 kg of steel each which is in total 10 metric tonnes of steel. As our calculation above shows, these 10 tonnes of steel reduce the carbon dioxide emissions by 17 tonnes. Since each kg of carbondioxide leads to 15 kg of melting ice this means 15 x 17 = 255 tonnes of ice-berg that is now saved from melting!

So, the next time you think about turning to a welded solution, take some time to think about when you will have to scrap them, or order in new ones and then imagine yourself being responsible for 255 tonnes of melting icebergs.

If you’re looking to reduce your companies emissions with a more environmentally friendly option, feel free to contact us today!

If you’re looking for a similar solution, contact us at sales@flexqube.com

You may also like:

3 tips on how to improve ergonomics in your material handling

A guide to the basics of successful material handling