How To Increase Productivity Using Tugger Carts for Material Handling

Regardless of how well run a manufacturing facility is, the fact remains that its productivity can still be increased if certain changes are made. In terms of material handling and transportation, the use of Tugger carts is one sure way of increasing productivity in multiple ways. The process of integrating a Tugger train system has been discussed here. So, in this post, the discussion will be about how you can increase productivity if you have installed or considering using Tugger carts.

3 Important Ways Tugger Carts Increase Productivity

Tugger carts have the capacity to enhance how manufacturers produce both district and generic items in the following ways:

Makes Just-in-time Delivery Possible

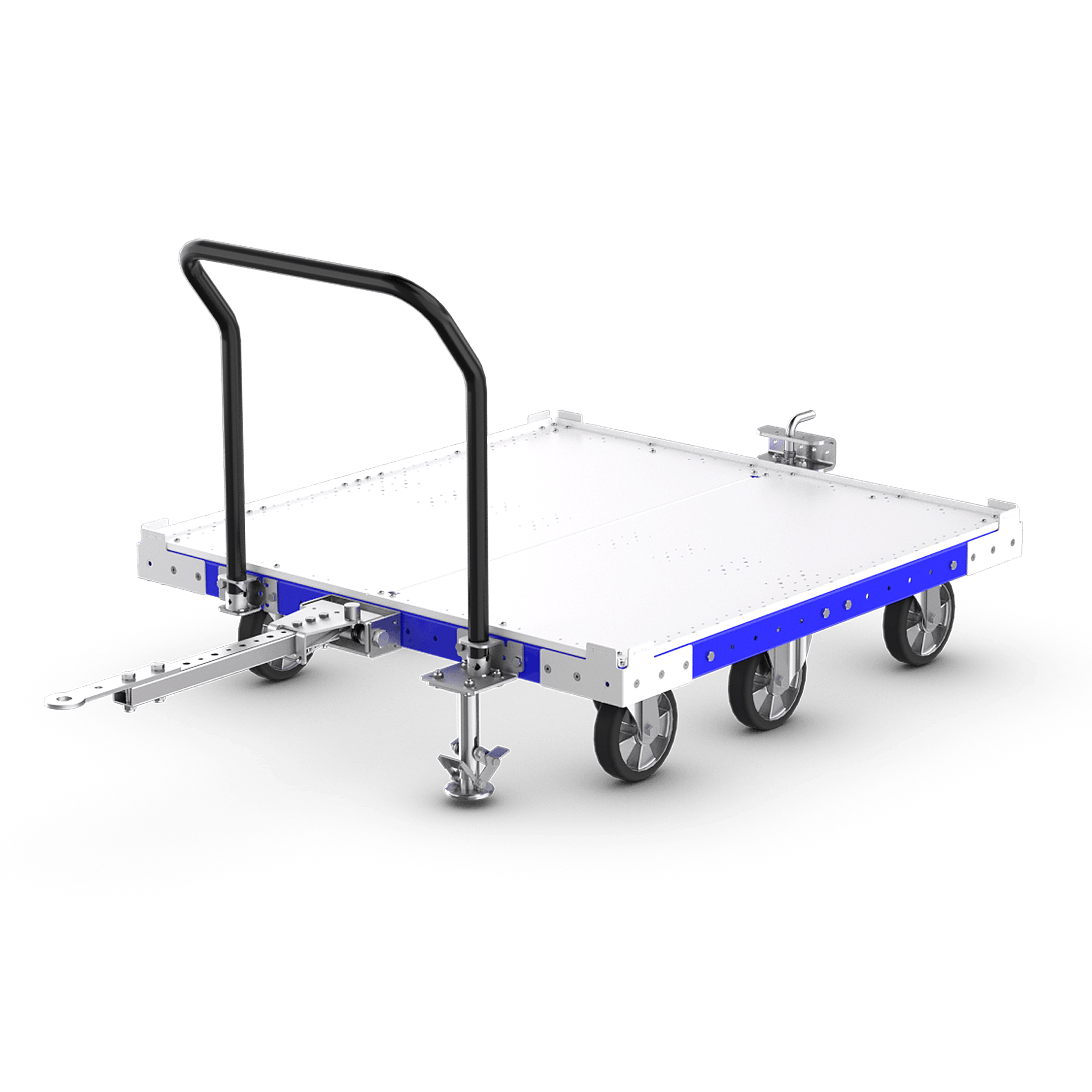

In factories where time is an important factor in determining how successful a production cycle is, Tugger carts can speed up delivery times. Tugger carts are versatile devices pulled by a guided vehicle. These carts can be ergonomically customized to fit specific material handling needs. While a forklift can carry only certain heavy duty goods, Tugger carts can handle heavy duty materials, small materials, and machining tools that are needed during production.

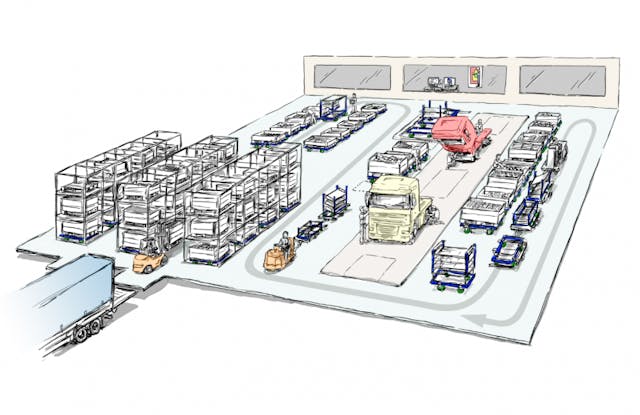

This means a Tugger train with multiple carts can provide multiple workstations with diverse materials and tools at need. The speed at which Tugger carts can be transported across shop floors also makes them great for just-in-time material delivery. The speed and versatility Tugger carts provide will definitely speed up production and eliminate downtime.

Reduce Shop Floor Traffic

The cumbersome nature of forklifts mean that they’re responsible for some of the traffic that occurs in manufacturing facilities. With the application of Tugger trains, shop floor traffic can be drastically reduced or eliminated in some cases. This is due to the very nature of a Tugger train system. A Tugger train consists of just one driven vehicle that is attached to multiple rugger carts. When used, only one vehicle moves across the shop floor dragging the other carts along unlike forklifts were multiple driven vehicles are operated across the shop floor.

This mode of transporting numerous materials eliminates or reduces the possibility of shop floor traffic. Tugger trains are also versatile and to not obstruct foot traffic unlike forklifts. The ease at which they move through manufacturing facilities increases productivity and provides a measure of safety when transporting heavy materials.

A Variety of Configurations to Work With

Today’s Tugger carts have evolved to the stage where they can be used to support all the material handling requirements of a manufacturing facility. This is due to the different cart configurations you can work with and their ability to handle the heaviest of loads. Most tuggers can handle approximately 10,000 pounds of load and transport them using different cart configurations. For example, four-wheel steer carts are great for navigating narrow aisles. This is because they are engineered in such a way that their front wheels turn simultaneously with their back wheels. So when the Tugger turns, the carts easily maneuver through narrow pathways.

Also, the challenges that come with unloading materials can be solved by a mother/daughter configuration. The mother cart always holds the daughter cart in place and when the Tugger train reaches a station, a worker can simply pull out the daughter cart to access the materials. The option to work with different cart configurations and concepts also increases productivity. Users can also make use of flow carts to showcase tools or angled carts to make materials more accessible to factory workers. All these play a part in simplifying material transportation, providing assess to materials, and eliminating downtime.

Conclusion

Tugger systems are relatively more affordable than forklifts and leave a reduced carbon footprint when used. If interested in increasing productivity while driving an eco-friendly manufacturing process, rugger carts may just be theatrical handling equipment for your facility. You can learn more about the different rugger cart configurations available for your use by contacting us today.